The AD converter module system for data acquisition (DAQ) facilitates the rapid development of compact and high-precision data acquisition systems.

The ADCstamp is particularly suitable for extremely precise measurements and tests of electrical signals and the monitoring of high-speed processes, as well as predictive maintenance and many other applications.

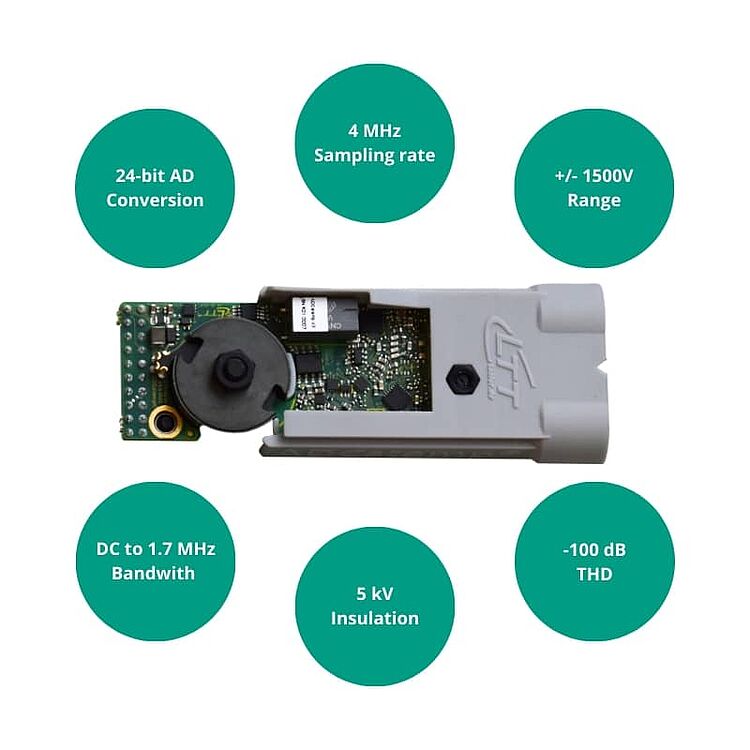

As a DAQ module solution, it covers all areas from signal conditioning to conversion and processing. At the same time, the signals are protected from external interference by galvanic isolation. Thanks to the flat bandwidth of the module, which ranges from DC to 1.7 MHz, both very low frequencies and signals in the higher frequency range can be recorded without compromising the quality of the measurement.

The ADCstamp impresses with its 24-bit AD conversion and high sampling rate of up to 4 MHz, allowing the analogue signals recorded by the sensors to be digitized with exceptional accuracy.

Various input types (AC/DC, unipolar, bipolar, single-ended, differential-ended) can be connected to the ADCstamp. The module board is only 68.2 mm x 25.4 mm in size, which greatly reduces the space required compared to conventional modules. Several modules together can also be used highly synchronously in a multi-channel application.

Each ADCstamp has a measurement channel whose digitally adjustable gain offers perfect optimization of the dynamic range.

The AD converter module allows commissioning in just a few minutes thanks to clear design specifications, FPGA source code examples and complete FPGA starter kits (e.g. ST1+XU5 from Enlcustra).

Find out from us personally how the ADCstamp can help you and contact us!