Read our application reports and learn more about the use of our LTT precision measurement technology

![[Translate to English:] Materialtests an Gasturbinenschaufeln [Translate to English:] Materialtests an Gasturbinenschaufeln](/fileadmin/_processed_/e/4/csm_Application_on_gas_turbines_b57d7b3e09.jpg)

LTT measurement technology contributes to ensuring safety and efficiency through exciting material tests on gas turbines.

Learn more about material testsThe transition to Industry 4.0 presents companies with major challenges. However, high-performance measurement technology can help to reduce machine downtimes and ensure quality assurance.

More about measurement technology applications in Industry 4.0

![[Translate to English:] Ansprengungen](/fileadmin/_processed_/7/e/csm_Ansprengungen_e885742cb3.jpg)

Precise calculation models are important - but how reliable are they without real tests?

Our robust LTT24 in an action-packed field of application.

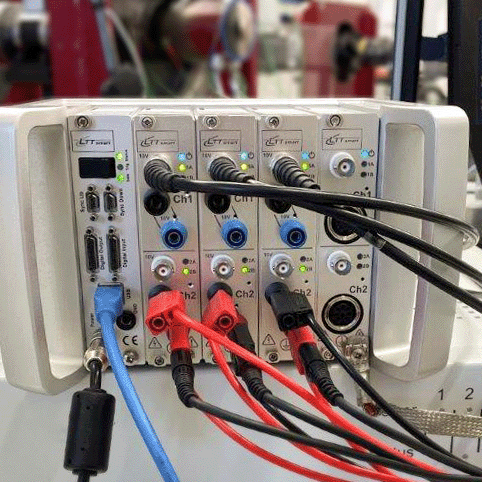

Read full reportThe further development and optimization of passive safety systems is an important topic in the automotive industry. In the future, even faster activation times and even more sensitive reactions will be required. To achieve this, the LTTsmart is used to measure and evaluate the structure-borne sound generated during a crash.

Read the full report

The cabling in vehicles is exposed to extreme loads. There are strong vibrations and large temperature differences. To withstand these conditions, components such as cable harnesses, connectors and switches are intensively tested on shakers and in heat chambers. Even the shortest connection dropouts must be reliably detected.

More about signal dropoutsPower measurements in the aviation industry on integrated systems increase efficiency!

The LTTsmart in use on integrated drive systems.

Read more about measurements in the aviation industry

EMC measurements are extremely important for the safe operation of track switching devices. A report on the use of our LTT24.

To the EMC reportLVDT/carrier-supplied DMS sensorsare not commonly used. But when they are, they pose major challenges for measurement technology. This is especially true for large-scale projects with multiple measurement channels. The LTT24 from Labortechniker Tasler GmbH is the market leader for such tasks and many more.

To the report with LVDT

WITTENSTEIN SE develops customized products, systems and solutions for highly dynamic motion, high-precision positioning and intelligent networking in mechatronic drive technology. Labortechnik Tasler provides support here.

Read the application report on electrical power measurement on servo actuators by the LTTsmart Power Analyzer here!

Details on power analysis on servo actuatorsOn duty for Tomocon!

The LTT24 in use for the measurement of liquid metals and their structure, by the HZDR (Helmholtz-Zentrum Dresden) as part of the EU project Tomocon.

More details and video

Human activity underwater generates enormous noise levels that have a dramatic impact on the marine environment. Marine researchers analyze these underwater sounds - with the best equipment available on the market: the LTT24

To the report on marine researchAn industry on the move: Only a few measurement technology manufacturers can keep up with the rapid development of electromobility. With the LTTsmart, you are on the safe side.

To the report on electromobility

LTTpro is the associated software for display, analysis and storage of the data, so that the measurement chain from sensors to data acquisition to software can be offered from a single source.

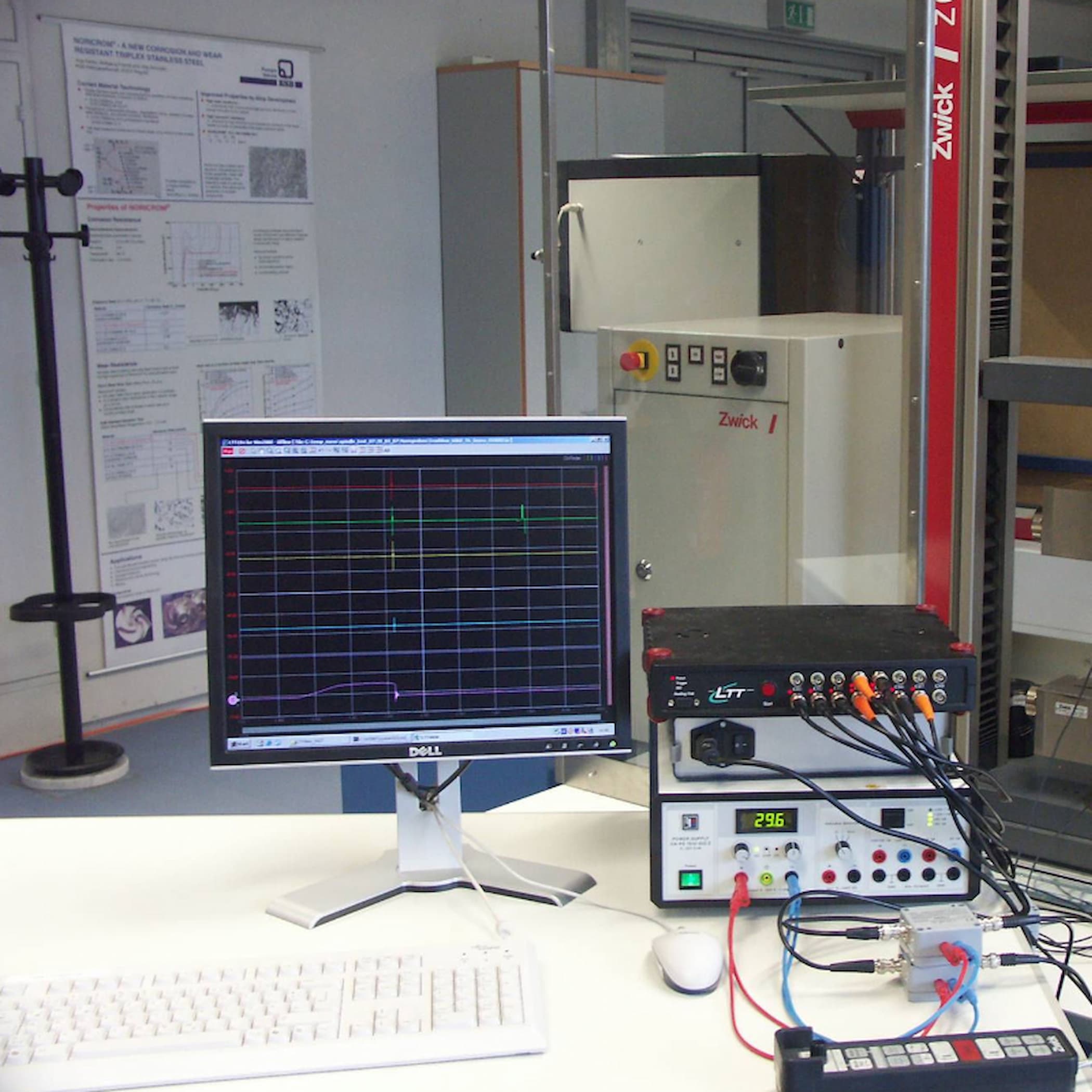

More about power analysis with LTTproProcess monitoring of grinding operations relies on structure-borne sound sensors, which have a very high bandwidth.

Details of process monitoring

Electric drives are conquering our daily lives: cordless screwdrivers, angle grinders, electric bikes and electric cars must function with maximum efficiency over the greatest possible load ranges.

Test standards, such as the DIN IEC 60034-2-3, define the test requirements for determining the efficiency of such inverter-fed drives. The LTTsmart is the only device worldwide offering the necessary bandwidth and accuracy.

Details of measurements of electric motorsCongratulations for the 1st place of the Innovation Award 2017 of the district of Göttingen!

The company "friends of green sonic" developed together with Labortechnik Tasler GmbH a new recorder for music recordings: A 24-bit PCM system with a sampling rate of 4.2336 MHz - digital audio redefined.

Details of digital music recording

Acoustic measurements in air are often carried out with microphones corresponding to the ICP® standard and therefore require a constant current supply.

More of acoustic measurementsThe Center for Building Materials and Materials Testing (cbm) at the Technical University of Munich is one of the most important research and testing institutes for building materials in Germany. The cbm's field of activity covers the areas of teaching, research and materials testing. The Concrete Technology working group deals with the essential aspects of concrete as a building material - from production (mixing) and processing (rheology) to mechanical properties and durability.

Details of material testing

Continental chose the LTT186-16 transient recorder from Labortechnik Tasler.

The device has proven itself both in stationary test bench operation and in mobile "crash use". This is because the upcoming tests require a powerful measurement data acquisition system that meets particularly high requirements. The system must be able to operate autonomously, i.e. without computer support, and must also be able to record data for extended periods of up to several minutes. It should also offer a high signal bandwidth of up to 1 MHz for as many channels as possible, and this with the highest accuracy.

Today, use the LTT24 as a successor model.

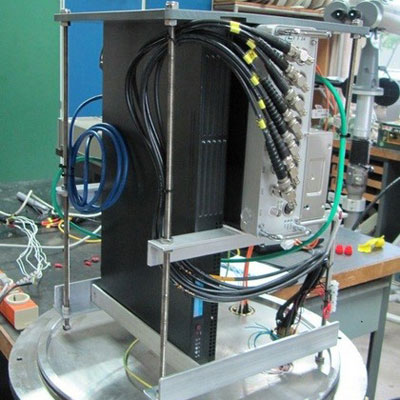

Details of crash testsTU Munich - The company EADS-Astrium commissioned KRP-Mechatec to test a mechatronic satellite component, a so-called "Low Shock Release Unit" (LSRU), which the client had developed and built for use on satellites.

Today, you use the LTT24 as the successor model.

Details of qaulification tests

The recording of underwater pressure waves places great demands on the measurement technology used. High sampling rates are required for the transient signals of a blast, as well as robustness of the measurement system against shock and vibration.

Today, you use the LTT24 as a successor model for this purpose.

More details of unterwater blasting testsDecentralized acquisition of strain gauge sensors on a gas turbine: As part of the continuous further development and optimization of its products, the Power Generation Group within Siemens AG operates a test field for investigations on gas turbines at the gas turbine plant in Berlin. The demands on the measurement technology are enormous: Typically, more than 300 dynamic channels with sampling rates of up to 50 kHz per channel have to be acquired.

Today, you use the LTT24 for this as the successor model of the data logger.

More about measurements on gas turbines

Robust transient recorders also prove themselves over the long haul and ensure fast and reliable recording of measurement data.

More about such measurementsUltra-fast measurement technology on engine test benches at the Institute for Engine Construction with the patented LTT measurement method.

To the report![[Translate to English:] Präzisionsmessgerät LTT24 bei Aussetzer-Messungen [Translate to English:] Präzisionsmessgerät LTT24 bei Aussetzer-Messungen](/fileadmin/media/Bilder/Applikationsberichte/Aussetzer/Aussetzer-400px.jpg)

Transient recorders from Labortechnik Tasler GmbH were used as a replacement for tape recorders in blasting tests, among other things. The possible effects on the occupants are investigated. For this purpose, test dummies and seat structures are equipped with sensors to determine the forces and accelerations applied. The measurement technology from Labortechnik Tasler is robust enough to record the measurement data directly in the blasted tank or building.

Learn mabout blasting tests